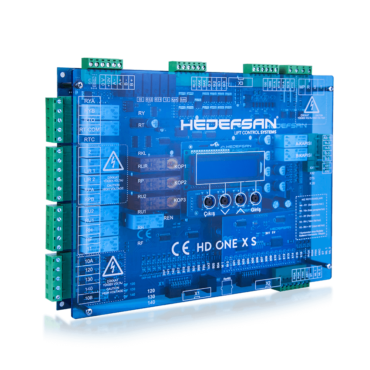

HD ONE XS

LIFT CONTROLLER CARDS

- +A3 Compatible

- +Internal Bridging Circuit

- +Easy Shaft Learning & Installation

- JET PRECISION DIGITAL MOTION

- SAFE RENEWABLE

- QUICK SETUP AND QUICK ACTIVATION

General Features

- The encoder-based shaft copying feature ensures precise monitoring of the elevator’s position, enhancing the system’s efficiency and reliability

- The built-in bridging early door opening function accelerates door opening processes, minimizing waiting times

- The open door leveling feature ensures the cabin remains at the correct level even when the door is open, maximizing passenger safety

- The ability to adjust floor settings from within the cabin, first developed by Hedefsan in Turkey, reduces commissioning labor while offering a user-friendly experience

- The 3 m/s speed support allows for safe and efficient high-speed operations, particularly improving performance in high-traffic areas

- The adjacent floor exit enables the elevator to move swiftly and efficiently between floors, saving time

- The ability to operate in up to four groups provides flexible usage in various building configurations, enhancing the system’s adaptability

- The call transfer feature in group operation optimizes elevator traffic, improving passenger satisfaction and system performance

- While 16 stops are supported as standard, this capacity can be increased to 32 stops if necessary, making it easily usable in high-rise buildings

- The call lamps and buttons are connected to the system with a single cable, simplifying the installation process and reducing maintenance costs

- Password-protected programming and PUK code protection against unauthorized use ensure maximum system security

- The last 20 errors can be monitored on the LCD screen along with floor information, speeding up fault detection and response time

- In standby mode, the LCD screen shows how long the elevator has been in operation, helping to optimize maintenance planning

- The adjustable maintenance period feature provides a warning on the LCD screen when it’s time for maintenance, facilitating scheduled maintenance activities

- The built-in terminal block simplifies the installation process and minimizes the risk of errors by saving on terminals

- The overload function provides an additional layer of protection to ensure the elevator operates safely and smoothly

- Short-circuit protected and individually adjustable display outputs for each stop offer safe and flexible use

- Display outputs can be converted to gray code or binary outputs, allowing the system to adapt to different requirements

- Direction arrows, out-of-service signals, and busy signals have SA relay contact outputs, and integration with signal partner inputs is possible

- Phases, phase sequence, and PTC (Motor temperature) are electronically monitored, and any faults related to these controls are displayed on the LCD screen, increasing the level of safety

- Fully compliant with the Elevator Directive (2014/33/EU), this system ensures your elevator operates safely and efficiently

Technical Features

| Model | Height(cm) | Width(cm) | Length(cm) | Weight(kg) |

| HD ONE X S | 7 | 22,5 | 32 | 1,9 |

- The system can operate with simple and collective control for up to 16 floors, providing adaptable solutions for different building requirements

- Call lamps and buttons can be connected to the system with a single cable, accelerating the installation process and reducing costs

- All parameters can be easily adjusted using the LCD screen and program buttons on the board, offering a user-friendly management experience

- Password-protected programming and PUK code protection against unauthorized use enhance system security

- The last 16 errors can be viewed on the LCD screen along with floor, direction, date, and time information, speeding up fault detection and response processes

- In standby mode, the LCD screen displays how long the elevator has been in operation, optimizing maintenance planning

- Adjustable maintenance intervals provide warnings on the LCD screen when maintenance is due, facilitating scheduled maintenance activities

- The built-in terminal block simplifies the installation process and saves on control panel terminals, minimizing the risk of errors

- The overload function provides an additional layer of protection, ensuring the safe and smooth operation of the elevator

- Short-circuit protected and individually adjustable display outputs for each stop offer safe and flexible use

- Display outputs can be converted to gray code or binary outputs, allowing the system to adapt to different requirements

- Direction arrows, out-of-service signals, and busy signals have SA relay contact outputs, which can be integrated with signal partner inputs

- Adjustable park floor and parking time options enhance the system’s flexibility

- A bi-stable switch input is available for position information, improving system accuracy

- An optional feature allows the cabin to be moved to the first floor when power is first applied, ensuring safe system commissioning

- If the door remains open for an extended period or the stop return circuit is not detected, a warning function on the LCD screen is activated, preventing potential safety risks

- Adjustable cabin light time, lock waiting time, floor waiting time, maximum high-speed time, and maximum low-speed time options provide flexible system usage

- The door opening signal (AUTO) and its operating mode can be selected based on direction arrows, improving system efficiency

- Program buttons allow for slow-speed manual movement, facilitating precise adjustments

- An option to display the first stop of the cabin on the display during each floor change provides useful information to the user

- During revision, the cabin can be moved to the limit switches or floor level, simplifying the maintenance process

- For elevators with only one fully automatic door, the floor with the fully automatic door can be selected, offering flexible usage

- Phases, phase sequence, and PTC (Motor temperature) are electronically monitored, and any faults related to these controls are displayed on the LCD screen, increasing safety levels

- This system, while not compliant with EN 81-20 or A3 regulations, is optimized to meet specific operational requirements.